Jun 30, 2025

Playing with time: embed objects in 3D prints

Embedding Different Materials in 3D Printed Objects

The 3D printing technologies, particularly FDM (Fused Deposition Modeling) 3D printing, has seen significant advancements, notably with the emergence of reliable, high-performance consumer-grade printers. Companies like Bambu Lab have nearly perfected FDM technology, making 3D printing accessible, reliable, and practical many people. This allowed lots of "regular" people to step into the realm of 3D printing, bring many new original ideas to the community.

Every manufacturing method comes with its unique set of constraints, and these constraints often drive the development of unique solutions. One such technique, now quite old in the 3D printing community, is the embedding of foreign objects within 3D prints. This approach offers significant advantages, primarily in creating robust and integrated assemblies that would otherwise be challenging or impractical to manufacture.

Commonly, users embed mechanical components such as nuts, magnets, or bearings directly into their prints. This provides a quick, easy, and physically strong method of joining parts. Before the widespread adoption of embedding, designers often relied on threaded inserts or attempted to model threads directly into their designs. However, consumer FDM 3D printers struggle to reliably create threads because it's impossible to make details so sharp and precise with soft and weak plastic. (Resin printers rock at this, but comes with their own constraints!) In addition, 3D printers can't print magnets. Therefore, embedding external components mid-print is a quick and easy solutions to many designs.

Beyond this, embedding also unlocks the ability to manufacture designs that are otherwise geometrically impossible using standard single-piece printing methods. (Print-in-place designs apply here as well.)

Consider this recent project I finished for Print-A-Smile @ ASU. I was tasked to create a safe and engaging toy for little children that can also be mass-produced.

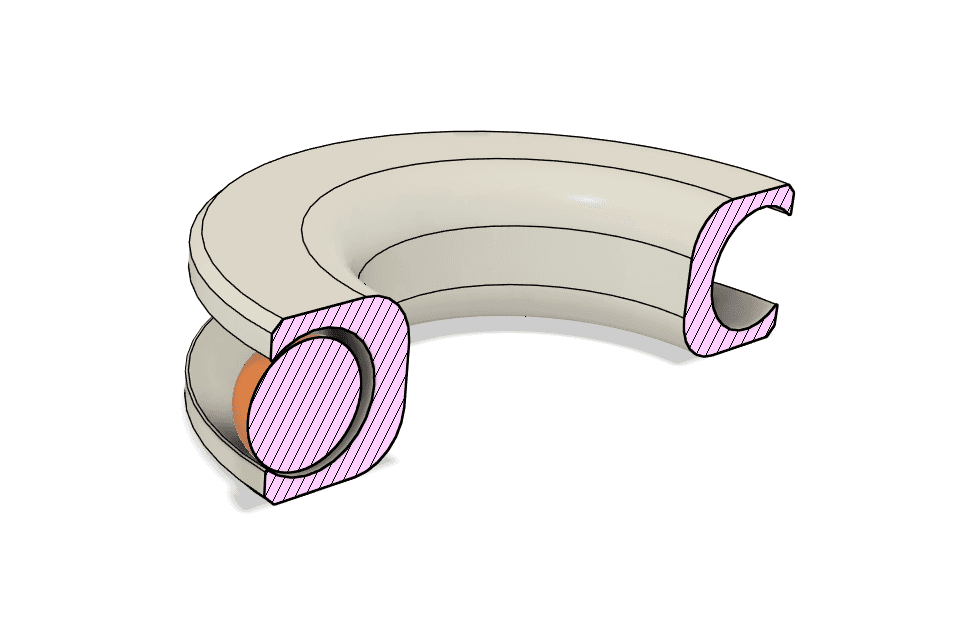

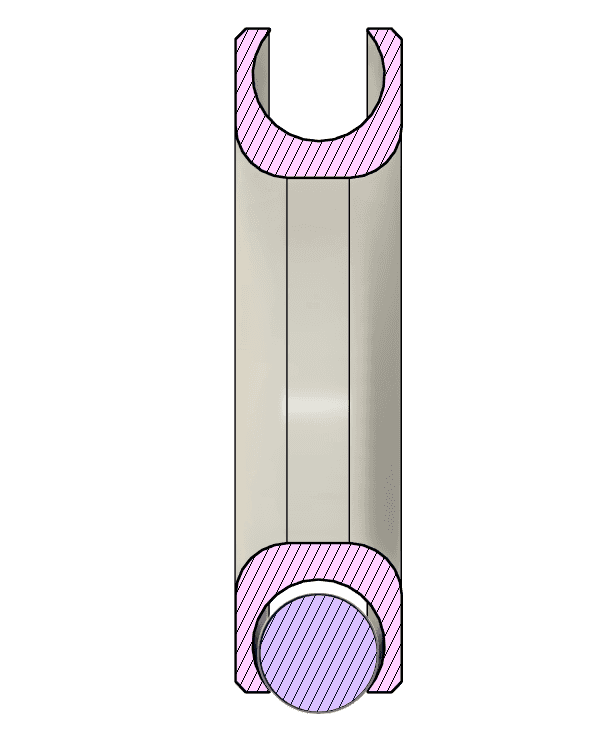

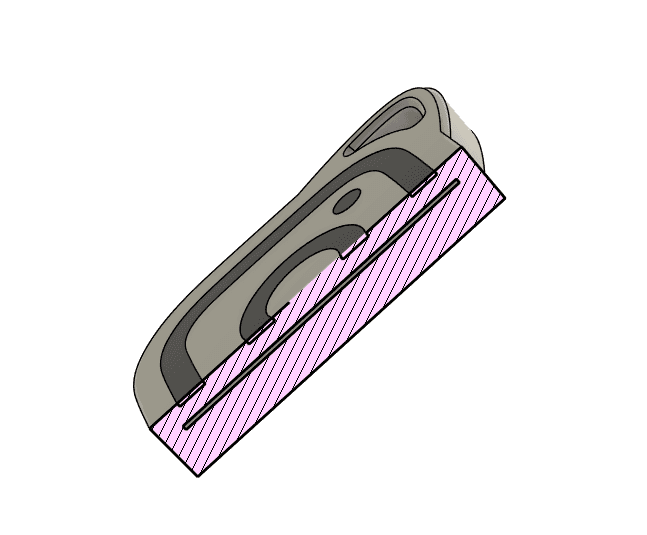

If you look at the section view, you'll quickly notice that this design is impossible to manufacture using standard, continuous printing methods. The circular channel is designed to contain a ball, preventing it from leaving, which inherently means the ball cannot enter the channel either. Given the toy's radial symmetry, there is not a entry point.

To produce such a toy using conventional manufacturing, one would typically resort to a multi-part design—perhaps splitting the object, inserting the ball, and then gluing or blocking the opening. While not overly complex, this approach is less conducive to efficient mass production.

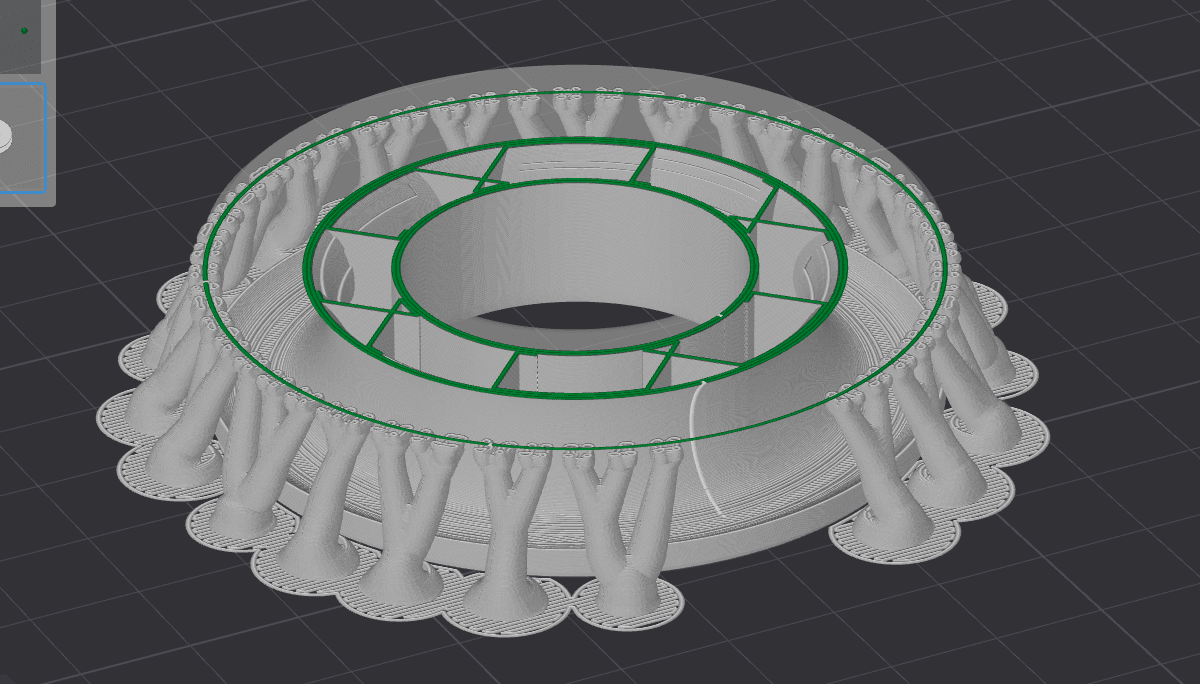

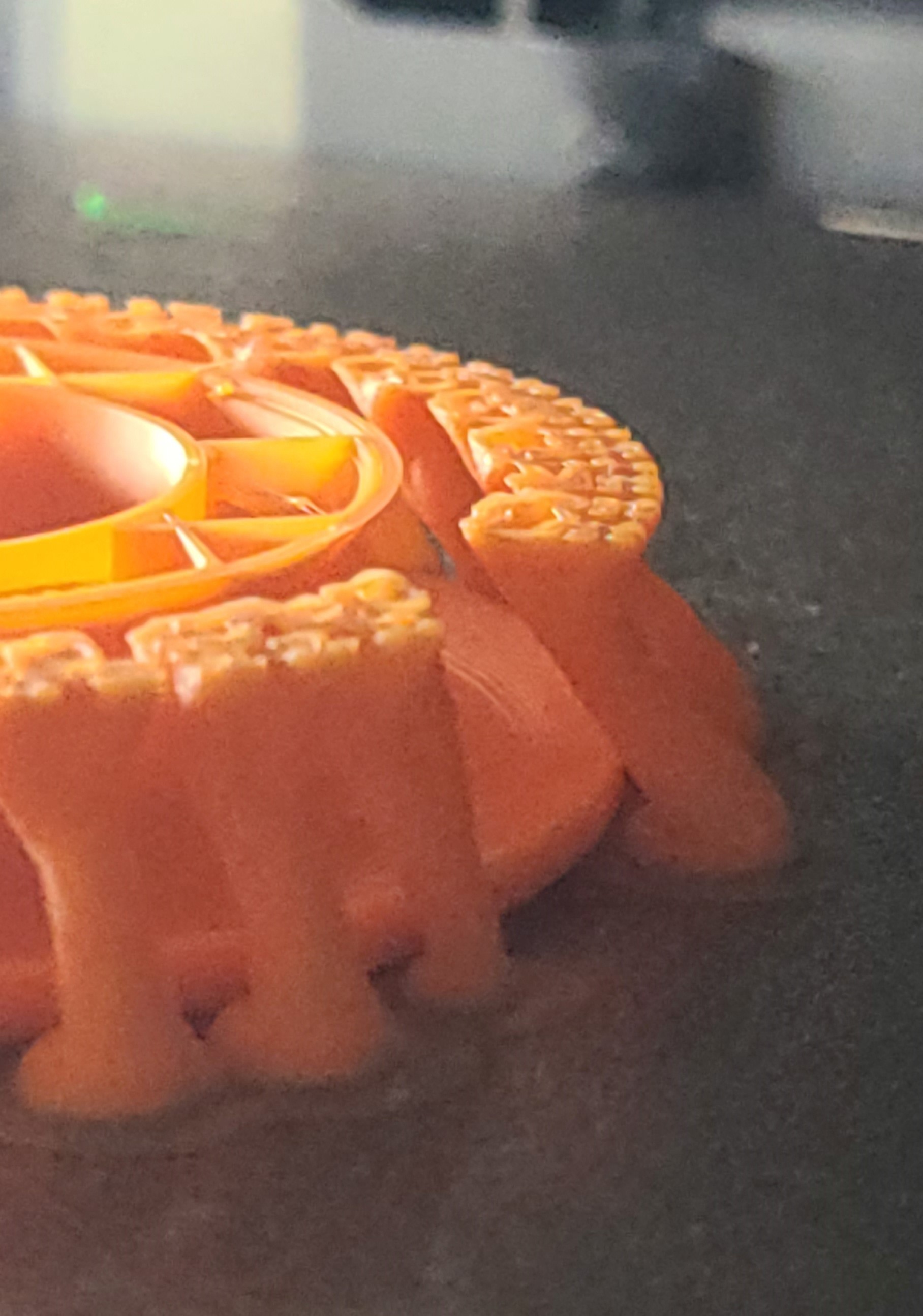

My solution leveraged a fundamental aspect of FDM 3D printing: its layer-by-layer additive process. Unlike injection molding, where an object is formed in a single step, FDM allows for precise control over each layer. This means I can pause the print at a specific layer, insert the desired component (in this case, the ball), and then resume printing as if nothing happened.

In this demo production model, I intentionally changed the filament color when I paused the print. At this stage, I could insert the ball and continue printing, resulting in a finished product directly off the 3D printer! This is very scalable as all copies of the object would need to pause at the same time to insert the ball.

Another fascinating application I recently explored is the embedding of NFC (Near Field Communication) stickers. This idea was inspired by observations during MakerWorld's "Reusing Cardboard Spools" contest, where some people tried to make use of Bambu Lab's (RFID but NFC-compatible) filament tags into the design. Although Bambu Lab's NFC tags are encrypted and cannot be reprogrammed, they can be effectively used with smartphone "Shortcuts" or routines to trigger various functionalities.

Inspired by this, I made an "Instagram Keychain" – though the concept applies to any social media platform. I designed a basic keyring in Fusion 360, incorporating a small hollow space in the middle specifically for the NFC sticker.

Similarly, the process involves pausing the print mid-way, inserting the NFC sticker into the designated cavity, and then completing the print. This technique makes such integrated designs feasible, as they would be exceedingly difficult to manufacture without the ability to embed components during the printing process.

Conclusion

Embedding materials within 3D printed objects significantly expands the capabilities of FDM technology. This technique offers a robust and efficient way to integrate various functional components, enables the creation of designs previously deemed impossible due to geometric constraints, and opens doors for incorporating electronic functionalities like NFC. By strategically pausing prints and inserting components, designers can overcome traditional manufacturing limitations, leading to more complex, functional, and innovative products directly from the 3D printer. As FDM technology continues to evolve, the creative applications of material embedding are bound only by imagination.